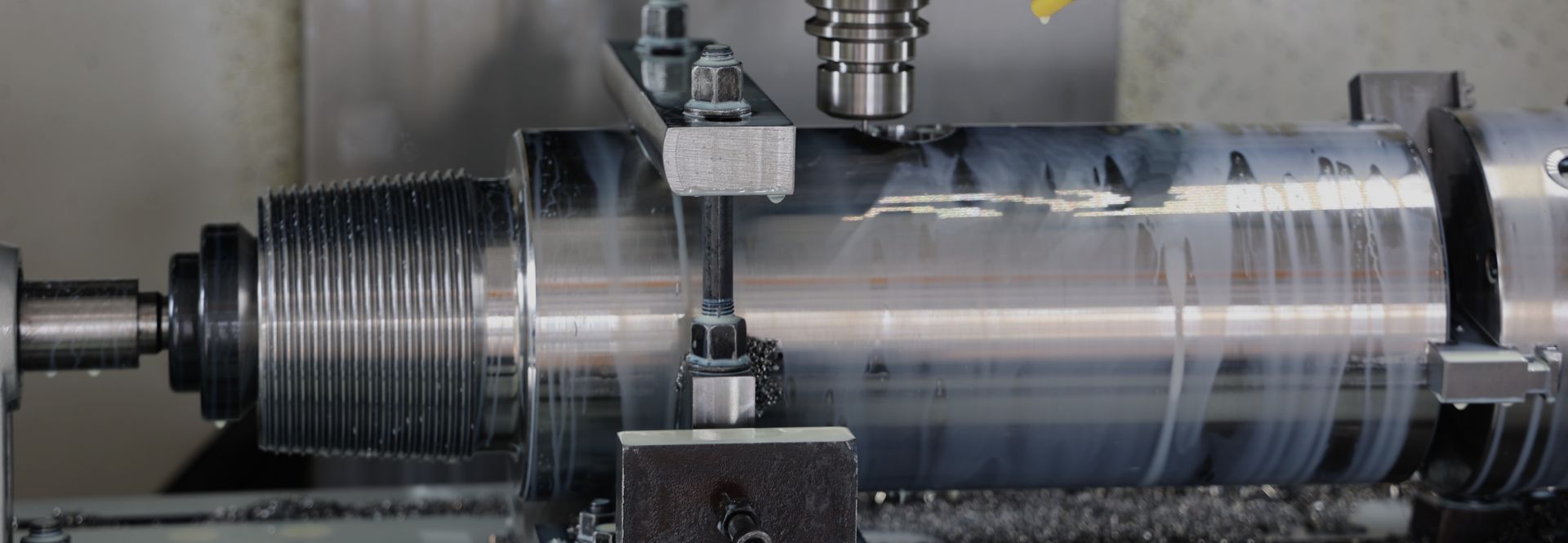

Super Washpipe Assembly adopts a new floating pre-compression structure. The floating upper part is connected to the swivel, which can solve the problem of end face deviation. The lower part is connected to the top drive main shaft, and adopts a pre-compression new packing box combined with a new material packing seal. The surface of the wash pipe adopts super wear-resistant coating technology, which greatly improves the overall service life.

1. Hammerless loading and unloading design, easy to disassemble and assemble with pawl tools

2. High-quality alloy steel materials are selected to ensure the strength of the washpipe

3. The most advanced military composite coating technology is used on the surface to ensure that the material has high wear resistance and extremely low friction, which increases the service life of the washpipe and packing

4. Imported special rubber seals are used to prevent H2S, high temperature resistance, wear resistance, and high elasticity, which is 3-5 times the life of ordinary seals

5. The packing skeleton uses special military composite cloth, which is extremely wear-resistant, 3-5 times the wear resistance of conventional skeleton cloth

6. Customizable, matching top drives and swivel of brands such as NOV, CANRIG, TESCO, MH, BENTEC, DRILLMEC, BPM, JH, TPEC, HH, ZPEC, etc.

Product parameters

Description | Super Packing Washpipe |

Seal Type | Packing |

Installation height | 282mm(customizable) |

Diameter | 3″/4"(customizable) |

Max. Working Pressure | 52Mpa(7500 PSI) |

Connection Thread | 6 1/4-3 Acme-LH(customizable) |

Working Medium | Drilling Fluid(Water or Oil Based) |

Gross Weight | 40KG/50KG |

Packing Dimension | 280*280*500mm |

Working Temperature | -45℃~177℃ |