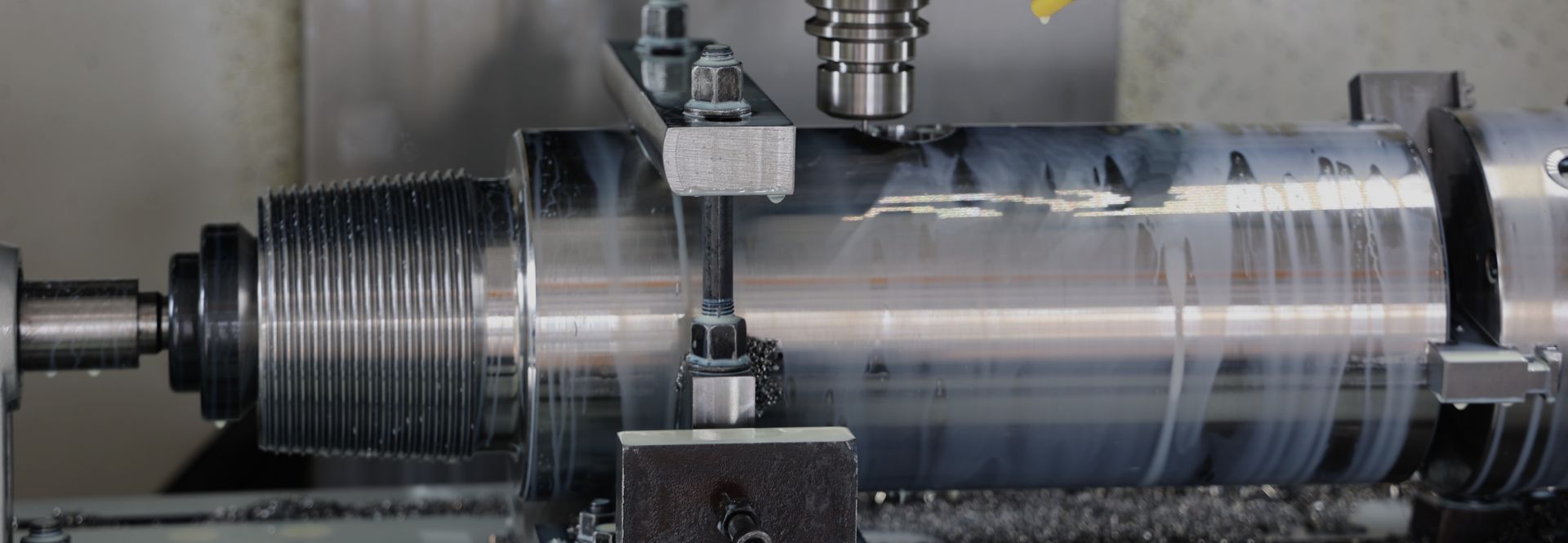

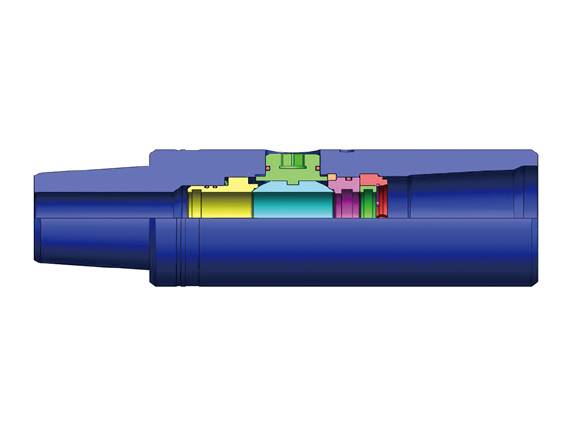

The Kelly Cock valve is a key equipment specially used in drilling and oil and gas production operations. Its main function is to control the flow direction of the fluid in the drill pipe and realize the rapid opening, closing and sealing of the fluid. As an important component in the drilling process, the kelly cock valve developed by our company has the characteristics of high strength, wear resistance, extremely low switching torque and long corrosion resistance life, and can operate stably under complex working conditions.

Features:

1. Super wear-resistant

The product adopts the new technology and special process of dual-phase tungsten-titanium material. It can maintain normal use under more than 10,000 pressure switch cycles in drilling conditions, and the product service life can reach 5,000 hours or more.

2. Low torque switch

The opening torque is ≤350N·mwhen the pressure is 35MPa; the opening torque is ≤1000N·m when the pressure is 60MPa.

3. Corrosion resistance

After the finished valve ball and valve seat are placed in vacuum special equipment, a layer of low-torque material is compositely infiltrated to enhance the surface finish, enhance the self-lubrication and anti-corrosion ability of the surface (according to NACE MR0175, it can resist H2S corrosion above EE level), which can reduce the rotation torque of the drill pipe plug valve by multiples, improve the wear resistance and corrosion resistance of the valve ball and valve seat surface, and greatly improve the product service life.

4. High pressure resistance

It can meet the different operating pressure requirements of 10000Psi and 15000Psi. At the same time, the 20000Psi drilling safety valve developed by our company has been successfully used in the drilling operation of the deepest well in Asia-Tako 1 well.

5. Easy maintenance

As a consumable part, the valve ball and valve seat repair kit can be replaced, which effectively reduces the drilling cost

6. Support customization

Product parameters

Sr. No. | O.D.-mm (in) | Water Course-mm (in) | Overall Length-mm (in) | Connection Thread |

1 | 89 (3 1/2) | 31.8 (1 1/4) | 590 (23.22) | NC26 |

2 | 105 (4 1/8) | 40 (1 9/16) | 590 (23.22) | NC31 |

3 | 108 (4 1/4) | 40(1 9/16) | 590 (23.22) | NC31 |

4 | 121(4 3/4) | 45 (1 3/4) | 610 (24) | NC38 |

5 | 127 (5) | 45 (1 3/4) | 610 (24) | NC38 |

6 | 168(6 5/8) | 71.4 (3 13/16) | 610(24) | NC50 |

7 | 168(6 5/8) | 71.4 (3 13/16) | 610 (24) | NC50 |

8 | 178( 7) | 71.4 (3 13/16) | 610 (24) | 5 1/2FH |

9 | 197 (7 3/4) | 76.2 ( 3) | 610 (24) | 6 5/8REGLH |

10 | 200 (7 7/8) | 76.2 ( 3) | 610 (24) | 6 5/8REGLH |