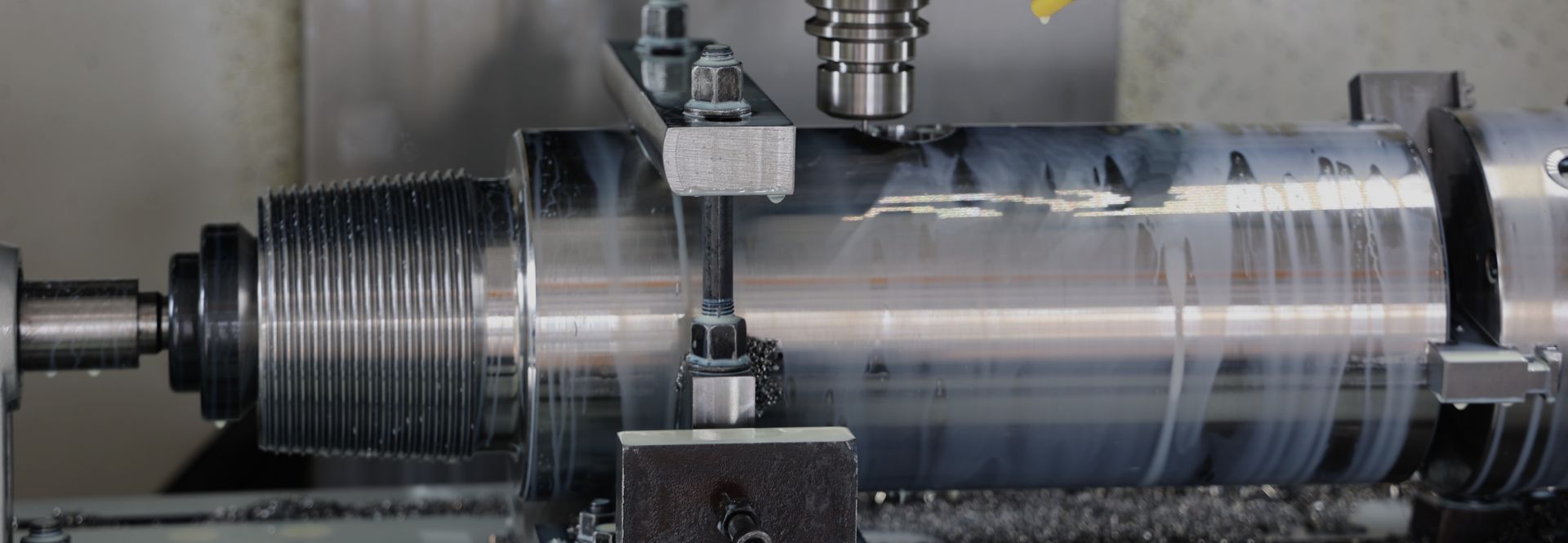

Chongqing Yinhe is the only manufacturer in China that has successfully applied the three core military technologies of low friction, high wear resistance and high corrosion resistance to drilling safety valves. The application of the three technologies has completely improved the performance of the safety valve, making the product fully possess the characteristics of low switching torque, high wear resistance and high corrosion resistance; the technical process has surpassed the international advanced level.

Features:

1. Super wear-resistant

The product adopts the new technology and special process of dual-phase tungsten-titanium material. It can maintain normal use under more than 10,000 pressure switch cycles in drilling conditions, and the product service life can reach 5,000 hours or more.

2. Low torque switch

When the pressure difference between the two ends is 35MPa, the opening torque is ≤350N·m; when the pressure difference between the two ends is 60MPa, the opening torque is ≤1000N·m.

3. Corrosion resistance

After the finished valve ball and valve seat are placed in vacuum special equipment, a layer of low-torque material is compositely infiltrated to enhance the surface finish, enhance the self-lubrication and anti-corrosion ability of the surface (According to NACE MR0175, it can resist H2S corrosion above EE level), and can reduce the IBOP rotation torque by multiples, improve the wear resistance and corrosion resistance of the valve ball and valve seat surface, and greatly improve the product life.

4. High pressure resistance

Yinhe IBOP can meet the different operating pressure requirements of 10,000Psi and 15000Psi. At the same time, the 20,000Psi IBOP developed by our company has been successfully used in the drilling operation of the deepest well in Asia-Tako 1 well.

5. Low maintenance cost

As consumable parts, the integrated design of the upper and lower ball valves reduces the time of making and breaking the buckle and improves the working efficiency.

6. Interchangeable and compatible

It can be matched and interchanged with the top drive IBOPs of most brands in the world, and perfectly matches the top drives of NOV, CANRIG, TESCO, MH, BENTEC, DRILLMEC, BPM, JH, TPEC, HH, ZPEC and other brands.

7. Support customization

It can be designed according to the size required by customers.

Product parameters-(taking φ197mm IBOP as an example)

Description | TDS Dual Ball IBOP valve |

Type | Dual Ball |

Rated Working Pressure | 68.9 Mpa-105MPa(10000Psi-15000Psi) |

Min. Working Pressure | 1.7Mpa |

Connecting Thread | 6 5/8 API REG box (code: 630) × 6 5/8 API REG box(code: 630) |

Length of the valve body | 800 mm |

Outer diameter | 197mm |

Inner diameter | 76.2mm |

Distance from stem center to top end | 265mm |

Packing Dimension | 820*220*310 mm |

Package Gross Weight | 170KG |

Stem hole | Inner hexagon S=22.5mm |

Make-up torque | 65~71KN.m |